How to choose the best glass sandblasting machine

If you work in the glass industry and want to integrate sandblasting into your production processes, choosing the right machine is essential to achieving high-quality results and efficiency. With so many options available on the market, there is a significant risk of purchasing a machine that isn’t suitable for your needs. How can you ensure that you avoid mistakes and make the best choice?

This guide will help you identify the perfect sandblaster for your needs, whether you’re buying your first machine, replacing an outdated model, or looking for a more advanced solution.

Which sandblasting technique should you apply?

First, assess the type of processing you plan to perform:

- Basic or advanced sandblasting? Some machines are designed for simple glass satin finishing, while others offer advanced features, such as gradient or zone-specific sandblasting.

- Specific applications? If you need to create detailed designs or logos, precision and control over abrasive pressure are essential.

If you want to learn more about the different sandblasting techniques and their practical uses, we recommend reading our complete guide to glass sandblasting.

Fratelli Pezza offers two lines of automatic sandblasters:

- Mistral EV+, an extremely versatile and comprehensive machine, suitable for both standard and advanced processes, such as zone-specific and gradient sandblasting. Thanks to its innovative technology, it allows for high-quality finishes with precise control over the pressure and speed of the nozzle. The intuitive software enables quick programming, optimizing production time.

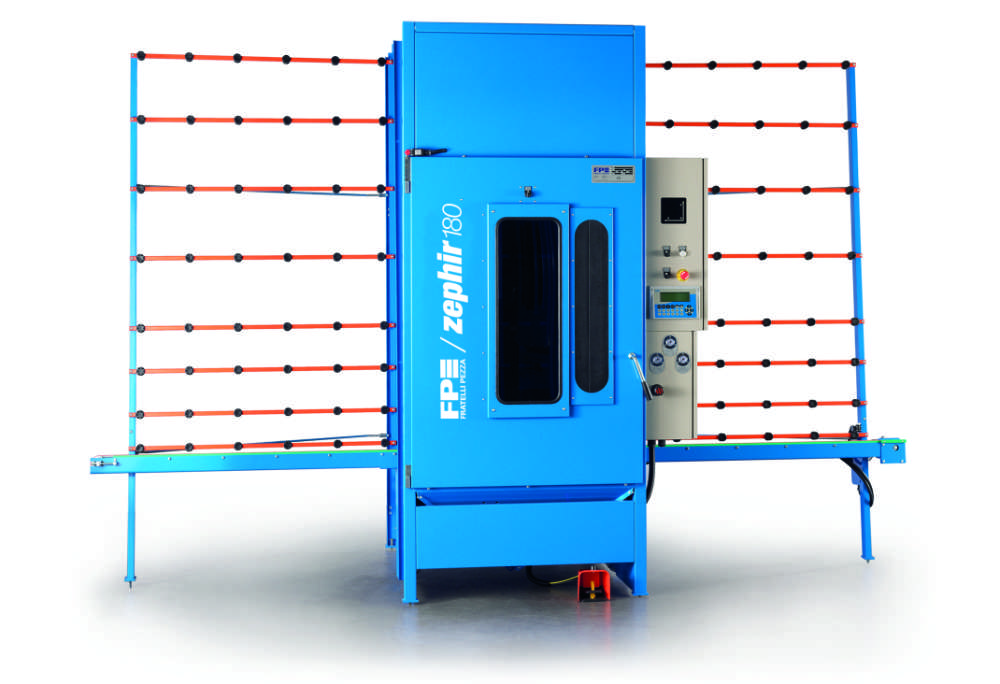

- Zephir+, a more affordable solution that maintains Fratelli Pezza’s reliability and quality, designed for those who need basic functions without sacrificing efficiency. It’s ideal for glassworks with lower production volumes, offering excellent precision in processing and a user-friendly interface.

Key factors in choosing a glass sandblasting machine

When choosing the right sandblaster for your glass production needs, there are several key factors to consider. Let’s take a closer look at the questions to ask before purchasing and the features to look for in a sandblasting machine that’s efficient, reliable, and suited to your projects.

Glass panel size to be processed

Sandblasters vary in size and loading areas. Make sure the model you choose can handle the glass panels you typically work with. If you work with large sheets, consider a system with a large working area.

Fratelli Pezza has developed three sizes of sandblasters to meet the most common needs. All models are “open top” and allow for processing glass panels taller than the working area. The maximum glass thickness is 50 mm.

Precision and work quality

If your business requires high-detail work, choose a machine with:

- Precise pressure and speed adjustment.

- Management software to easily customize parameters.

- CNC systems and advanced software to ensure perfect repeatability.

Mistral EV+ excels in all types of sandblasting thanks to its automatic regulation of pressure, passes, and nozzle speed. The software is simple and intuitive, with remote programming available via MistralApp.

Production volume

Every company has different production needs. If you need to sandblast large quantities of glass, an automatic machine with a continuous cycle will be more efficient than a manual model.

Fratelli Pezza sandblasters are designed to handle large volumes, with configurable parameters to achieve maximum performance and reduce downtime through preventive and predictive maintenance.

Ergonomics and ease of use

Ergonomics and ease of use are key aspects when choosing a sandblaster. An intuitive interface with simple controls allows operators to work with greater efficiency and precision. Advanced automation reduces manual intervention, simplifying the production process and lowering the risk of errors. The ergonomic design also plays an important role in ensuring operator comfort during long periods of machine use.

Fratelli Pezza sandblasters are designed to provide an intuitive and safe user experience, ensuring maximum reliability at every stage of processing.

Maintenance and technical support

An efficient machine must also be easy to maintain. Here’s what to consider:

- Quick access to components for easy maintenance.

- Spare parts available and easily sourced.

- Prompt and reliable technical support.

Fratelli Pezza sandblasters offer simple maintenance and, if performed regularly, ensure optimal performance. Our technical support is available by phone or via WhatsApp. Spare parts can be purchased online with delivery within 48 hours.

Operating costs and energy efficiency

In addition to the purchase price, consider the operating cost. Some models optimize abrasive consumption and the use of compressed air, reducing long-term costs.

Fratelli Pezza sandblasters are designed to maximize efficiency:

- Optimized abrasive consumption, down to the complete depletion of its abrasive capacity.

- Low energy consumption, both in terms of electricity and compressed air.

Why choose Fratelli Pezza Sandblasting Machines?

Fratelli Pezza sandblasters offer tangible advantages to improve production efficiency and reduce operating costs. Thanks to optimized energy and abrasive consumption, they provide significant savings without compromising on work quality. Additionally, the advanced dust management system ensures a cleaner and safer working environment, contributing to the well-being of operators.

The machines are designed to be extremely intuitive, with a simple interface and fast programming that makes daily work easier. On top of this, we offer fast and efficient technical support: free phone assistance and spare parts are always available, with guaranteed delivery within 48 hours.

Choosing the right sandblaster means balancing technical, production, and economic needs.

If you have any doubts or need personalized advice, feel free to contact us: our team is available to provide you with all the information you need and help you find the perfect solution for your business!